QualityEye®

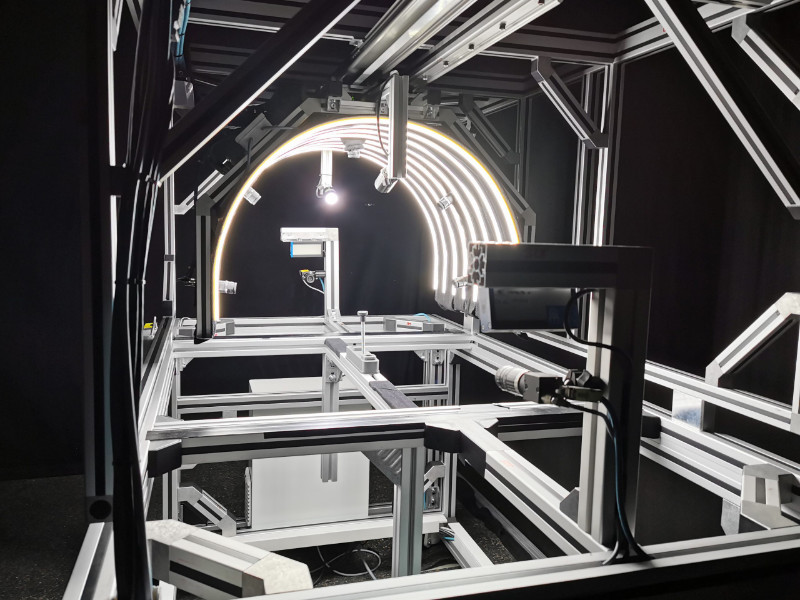

QualityEye® surface inspection system for the industrial production

With the QualityEye® product suite based on the EYYES framework, we develop and deliver forward-looking applications for more safety in quality inspection for defect detection and surface inspection with artificial intelligence.

- specifically designed to meet the needs of the industry

- camera-based

Inspection of a wide variety of surfaces

- Defect detection

- Defect classification

- Localised defect identification

- Comparative colour and gloss testing

Inspection of a wide variety of surfaces

- Defect detection

- Defect classification

- Localised defect identification

- Comparative colour and gloss testing

Detection of deviations using deep learning algorithms

- Workpiece identification

- Position determination

- Geometry recognition

- Weld seam detection

Specific optical AI solutions for machine producers to expand their own portfolio of offerings, such as

- Tool monitoring

- Inline quality inspection

- Optical evaluation for process control

-

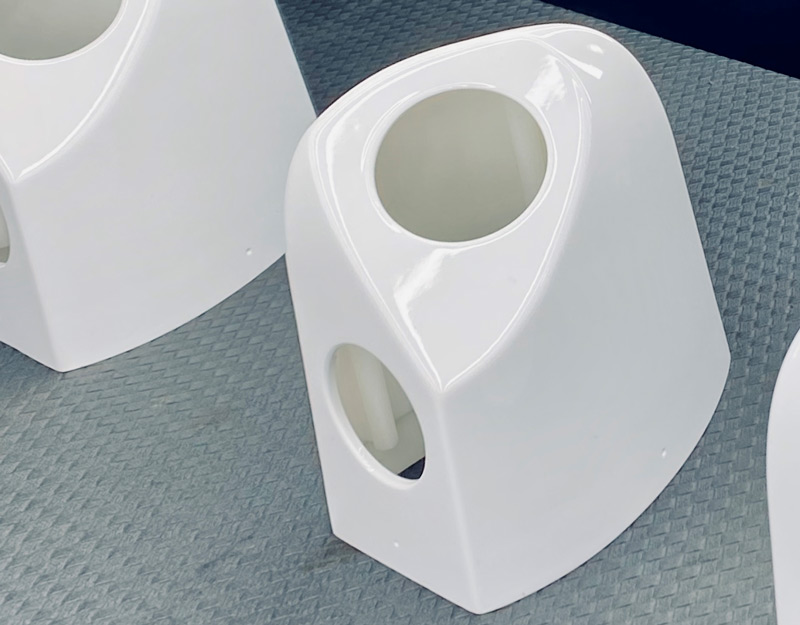

Surface Inspection

Inspects the surface of a painted or coated workpiece to detect defects in the surface, e.g.

- Scratches, dents

- Enclosed bubbles

- Inclusions of foreign particles

- Insufficient deburring

- Deviations of color and gloss level

-

Injection Molding

- Checks the dimensions of the product, e.g. for creep effects or spray defects

- Analyzes the color of the product, for example, by changes in the granules, color mist, paint runs, cloud formation

- Detects surface damage, e.g. scratches, dust inclusions, adhesive residues

- Even transparent components can be reliably inspected

-

Weld seam detection

-

- Real-time operation due to sampling rate of 90 fps

.

-

- 0% error rate

- >98% detection rate

- PLC interface to downstream industrial equipment

.

- Remote maintenance via VPN access

- Simple GUI for users

- Durable and robust

- Flexible design

-

Contact us!